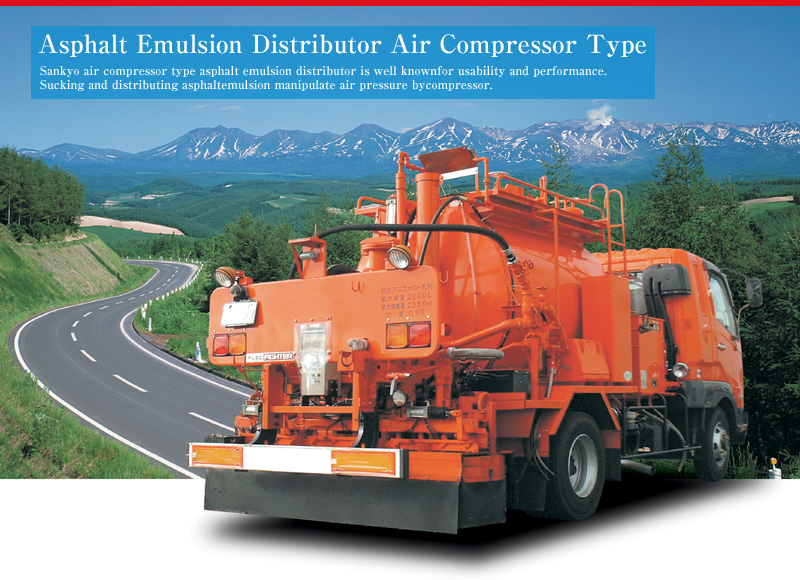

Feature

01 Spray-Bar

Distributing asphalt emulsion equally is the most important performanceof the distributor. Our distributor is able to do that because we haveenough experience and high technology of this area. To adjust theheight and width spray bar can choose manual operation and automaticoperation by oil pressure.

02 Air Flushing

Distributing asphalt emulsion uses air pressure system. Because thissystem can remove all remained asphalt emulsion from the pipe or to thetank, it is not clogging problems.In addition, air flushing can be used to the nozzle. When turning off theswitch, this system automatically starts flushing for resolving to clognozzle and to drip off asphalt emulsion.

03 Safety Equipment

Our distributor is installed some ideas which workers can work safetyeven during night. For example, the light for the backward and the tires.The backward monitor is liquid crystal screen, so workers can recognize obstacles easily.

|

|

The StrainerThis resolves clogging problems |

The FlashlightWe provide a various type of the flashlight as an option. |

|

|

The Upper StepBecause the work place is wide on the tank, workers can work safely. |

The Tool BoxThe size is long,so boots can be put in. |

|

|

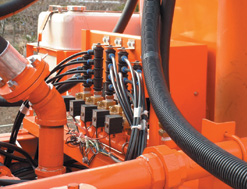

The Operation SwitchesThese switches are effectively arranged for manipulating of this machine. |

Nozzle Air WashingAfter distributing, the nozzle is washed by air for 2-6 seconds.This resolves clogging problems and dripping asphalt emulsion. |

|

|

The Lifting Unit |

The Extensible Unit |

|

|

Air flushing Solenoid Valve |

The Outside Operation BoxThis box is put on the rear because it can be used for adjusting high and width of spray bar. |